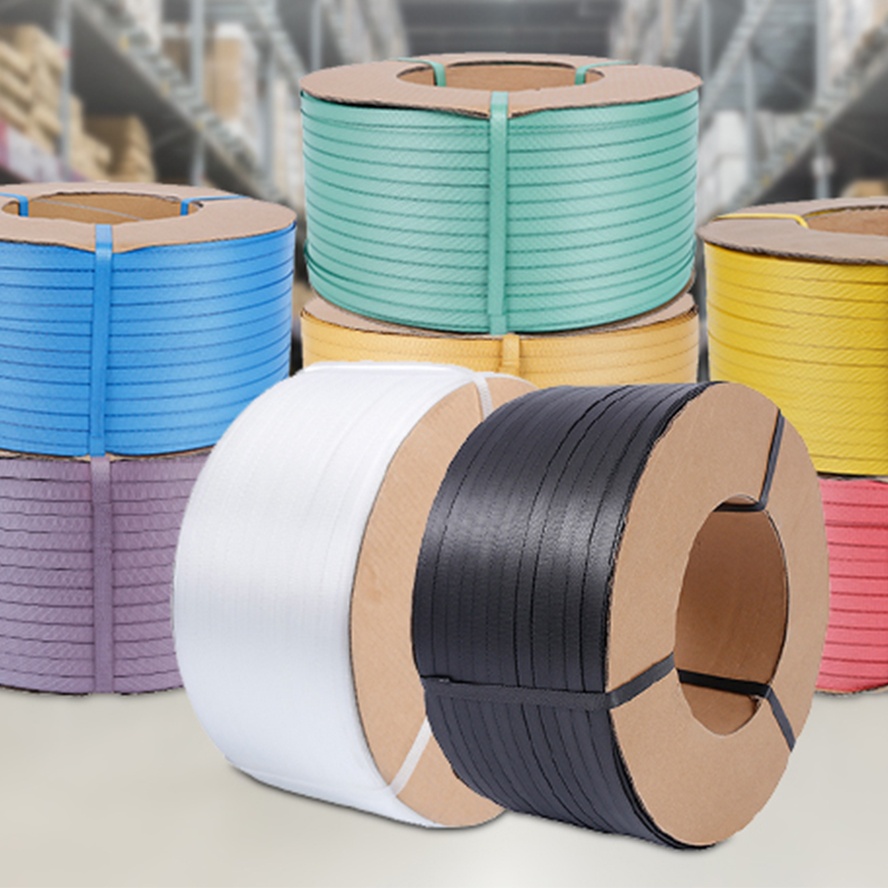

Precautions for Using high-quality polypropylene strapping band are a popular choice for the packaging industry due to their durability, strength and cost-effectiveness. However, like any other product, polypropylene straps must be used with caution to ensure they are used safely and effectively. In this article, we will discuss the precautions that must be taken when usinghigh-quality polypropylene strapping band.

Proper Handling

Proper handling is crucial when using high-quality polypropylene strapping band. These straps are made from a synthetic polymer, which means they can be quite slippery. It’s important to handle them with care to avoid any accidents such as slipping or dropping. Additionally, it’s important to ensure that the straps are not twisted or kinked, as this can weaken the strength of the strap and cause it to break.

Storage

Proper storage is also important when using high-quality polypropylene strapping band. These straps should be stored in a dry, cool, and well-ventilated area to prevent damage from moisture or extreme temperatures. Additionally, it’s important to ensure that the straps are not stored in direct sunlight, as this can weaken the strength of the strap and cause it to break.

Loading and Tensioning

When using high-quality polypropylene strapping band, it’s important to ensure that they are loaded and tensioned correctly. Overloading the straps can cause them to break or stretch, which can be dangerous and damage the goods being transported. It’s also important to ensure that the straps are tensioned correctly, as this can affect the strength of the strap and the stability of the goods being transported.

Inspection

Regular inspection is crucial when using high-quality polypropylene strapping band. These straps should be inspected before each use to ensure that they are in good condition. Any straps that are damaged or worn should be removed from service immediately and replaced. This can help to prevent accidents and damage to the goods being transported.

Training

Proper training is also an important precaution to take when using high-quality polypropylene strapping band. It’s important to ensure that all employees who will be using the straps are properly trained on how to handle, load, tension, and inspect them safely. This can help to prevent accidents and ensure that the straps are used effectively.

In conclusion,high-quality polypropylene strapping band are a popular choice for the packaging industry due to their durability, strength and cost-effectiveness. However, it’s important to take precautions when using these straps to ensure that they are used safely and effectively. Proper handling, storage, loading and tensioning, inspection, and training are all important precautions to take when using high-quality polypropylene strapping band. By following these precautions, packaging companies can ensure that their products are safely and securely transported and that their employees are protected from accidents.

In addition to the precautions mentioned above, it’s also important to ensure that the proper equipment is being used when working withhigh-quality polypropylene strapping band. Using the right tools, such as manual or automatic strapping machines, can make the process of securing and transporting goods much more efficient and safe. It’s important to ensure that the equipment is in good working condition and that employees are properly trained on how to use it.

Another important precaution to take is to ensure that the polypropylene straps are the correct size and strength for the goods being transported. It’s important to select the appropriate width and thickness of the strap depending on the weight and dimensions of the goods being packaged. Using a strap that is too thin or weak for the load can lead to breakage or stretching, which can be dangerous and damage the goods being transported.

It’s also important to ensure that the polypropylene straps are applied correctly, with the correct amount of tension. This ensures that the goods are securely packaged and protected during transportation. it’s crucial to follow the manufacturer’s instructions when it comes to tensioning and securing the straps.

Finally, it’s important to dispose ofhigh-quality polypropylene strapping band properly when they are no longer in use. These straps are made of synthetic polymer and should be recycled or disposed of properly. Failing to properly dispose of these straps can have negative effects on the environment and can also be a potential hazard if not handled correctly.

In conclusion, using high-quality polypropylene strapping band is a cost-effective and efficient way to secure and transport goods. However, it’s important to take necessary precautions to ensure that these straps are used safely and effectively. Proper handling, storage, loading and tensioning, inspection, training and equipment, selecting the right size and strength, correctly applying the straps and proper disposal are all important considerations when using high-quality polypropylene strapping band. By following these precautions, packaging companies can ensure that their products are safely and securely transported and that their employees are protected from accidents.

Related Products