Packing and securing items for transportation or storage can be a challenge, especially when it comes to heavy loads. To make the process easier and more effective, many businesses turn to strapping methods. However, with so many options available, it can be difficult to determine which method is best. In this article, we will compare PP packing strip from China factory and traditional strapping methods to help you make an informed decision.

I. Introduction to PP Packing Strip

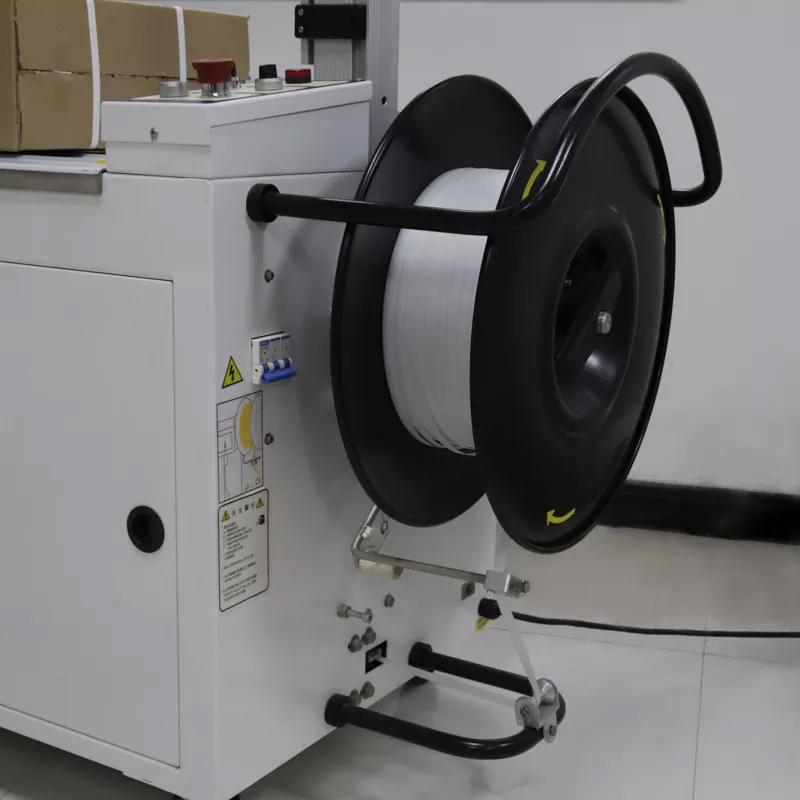

PP packing strip from manufacturer, also known as polypropylene packing strip, is a type of strapping material that is made from polypropylene, a durable and flexible plastic. It is designed to be used as a substitute for traditional metal strapping and is becoming increasingly popular due to its many advantages.

II. Advantages of PP Packing Strip

A. Lightweight and Easy to Handle

One of the biggest advantages of PP packing strip from supplier is that it is lightweight and easy to handle, making it a convenient choice for packaging and securing items. This makes it ideal for use in a variety of industries, including manufacturing, transportation, and storage.

B. Durable and Resistant to Weather and Chemicals

Another advantage of PP packing strip from China is that it is durable and resistant to weather and chemicals, making it a reliable choice for securing items for transportation and storage. This means that it will not rust, break, or become brittle over time, which can be a problem with traditional metal strapping.

C. Environmentally Friendly

PP packing strip is also environmentally friendly, as it is made from a reusable and recyclable material. This makes it a smart choice for businesses that are looking to reduce their environmental impact.

III. Traditional Strapping Methods

A. Steel Strapping

Steel strapping is a traditional strapping method that has been used for many years. It is made from steel and is known for its strength and durability. However, it can be heavy and difficult to handle, and it is also prone to rusting and breaking over time.

B. Nylon Strapping

Nylon strapping is another traditional strapping method that is made from nylon, a synthetic polymer. It is known for its high strength and resistance to weather and chemicals. However, it is not as strong as steel strapping and can be more expensive.

IV. Comparison of PP Packing Strip and Traditional Strapping Methods

A. Cost

One of the biggest differences between PP packing strip and traditional strapping methods is the cost. PP packing strip is typically less expensive than steel or nylon strapping, making it a more cost-effective choice for businesses.

B. Strength and Durability

In terms of strength and durability, PP packing strip is a close match to steel strapping. It is just as strong and durable as steel strapping, and it is also resistant to weather and chemicals.

C. Convenience and Ease of Use

When it comes to convenience and ease of use, PP packing strip is the clear winner. It is lightweight and easy to handle, making it a more convenient choice for packaging and securing items. This is especially true when compared to steel strapping, which can be heavy and difficult to handle.

V. Conclusion

In conclusion, PP packing strip is a versatile and cost-effective alternative to traditional strapping methods. Its many advantages, including its lightweight, durability, and resistance to weather and chemicals, make it a smart choice for businesses that are looking to reduce their costs and improve their packaging and securing processes.

Related Products